PRODUCTION OF VERSATILE, HIGH-PERFORMANCE, ENVIRONMENTALLY FRIENDLY LAMINATED DOORS AND PANELS

Lanta was established in 2016 to meet demand for laminated doors and cabinets, thus completing the extensive range offered by ILCAM Group, which stands out for its ability to draw on the full spectrum of industry technologies to produce components and accessories for the furniture sector.

The company’s original target market was Germany, but it quickly extended its reach by exporting across Europe.

Steady growth over the years backed by significant targeted investments in pioneering technologies to maximize quality and production efficiency have established the company as a market driver for the development of innovative solutions.

From the outset, Lanta’s journey has been steered by ESG principles, using products made from recycled materials, aligning with modern sustainability expectations.

TURNING INNOVATION AND QUALITY INTO OPPORTUNITY

A member of the ILCAM Group team since 2016, LANTA specializes in lamination and edging processes. It manufactures carcasses, cabinet doors and panels with highly versatile and delightfully tactile surfaces, including non-scratch and fingerprint-resistant options, along with innovative offerings in terms of sustainability, notably products made from recycled thermoplastic sheeting.

LANTA's philosophy informs its every decision and centres around the pursuit of flawless results through advanced production processes, a service tailored to customer requirements and painstaking quality control from material selection through to finishing.

PRODUCTS

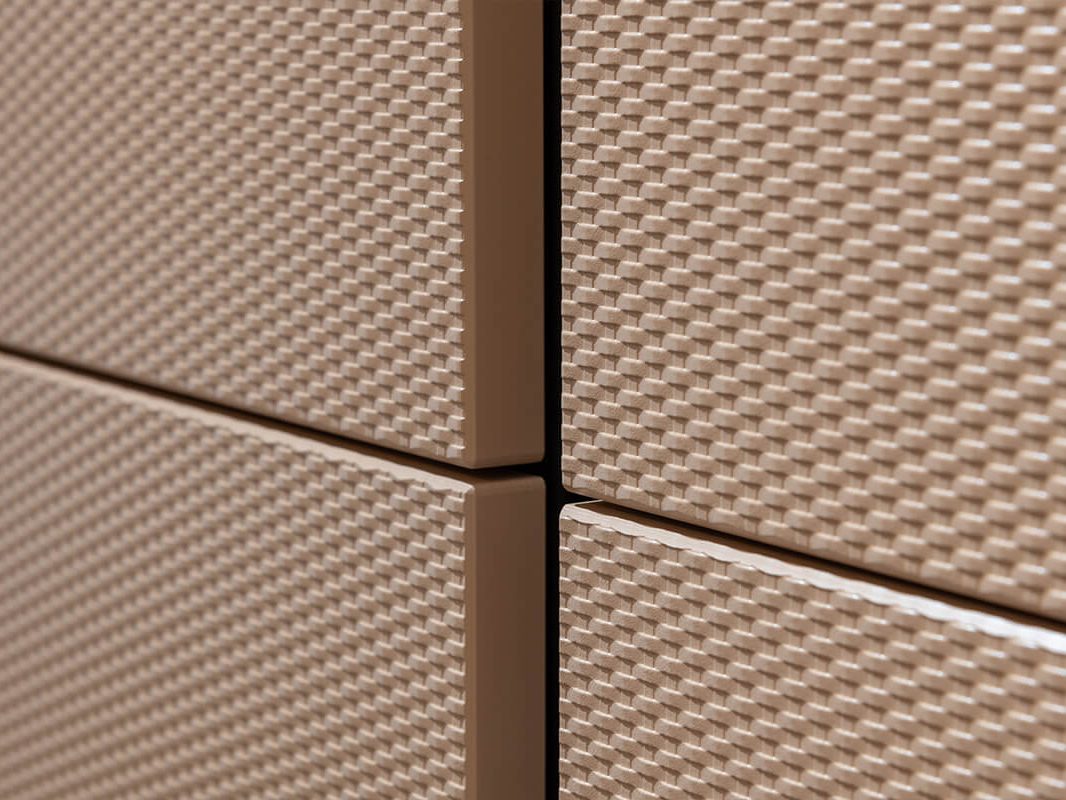

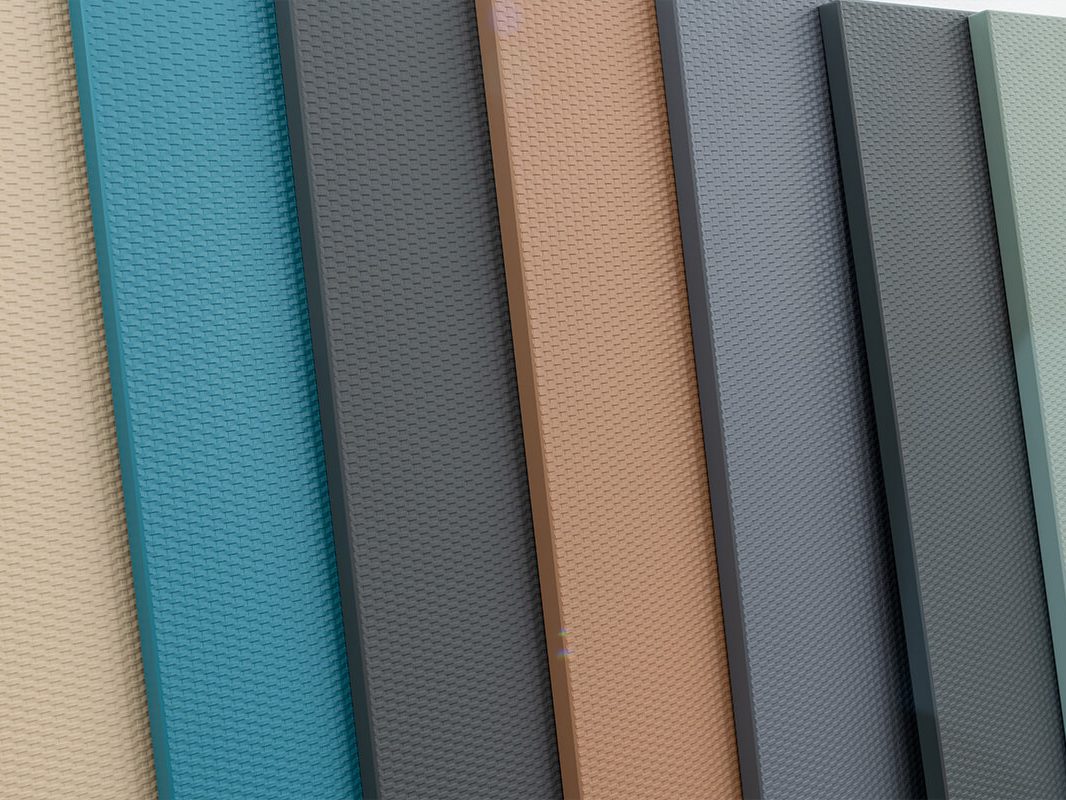

Limitless creativity in finishes and textured patterns

TAKTO-TEXture surface panels are the result of a unique technology which allows remarkably detailed industrial reproduction of any type of finish and decorative pattern on a layer of polybonded polymeric material. The special foil structure assures superior resistance.

Takto products are available in a rich range of standard styles, plus extra custom colour options achieved by adding colour in the layer, painting or applying foils also made with recycled materials.

Planet-friendly durability and beauty

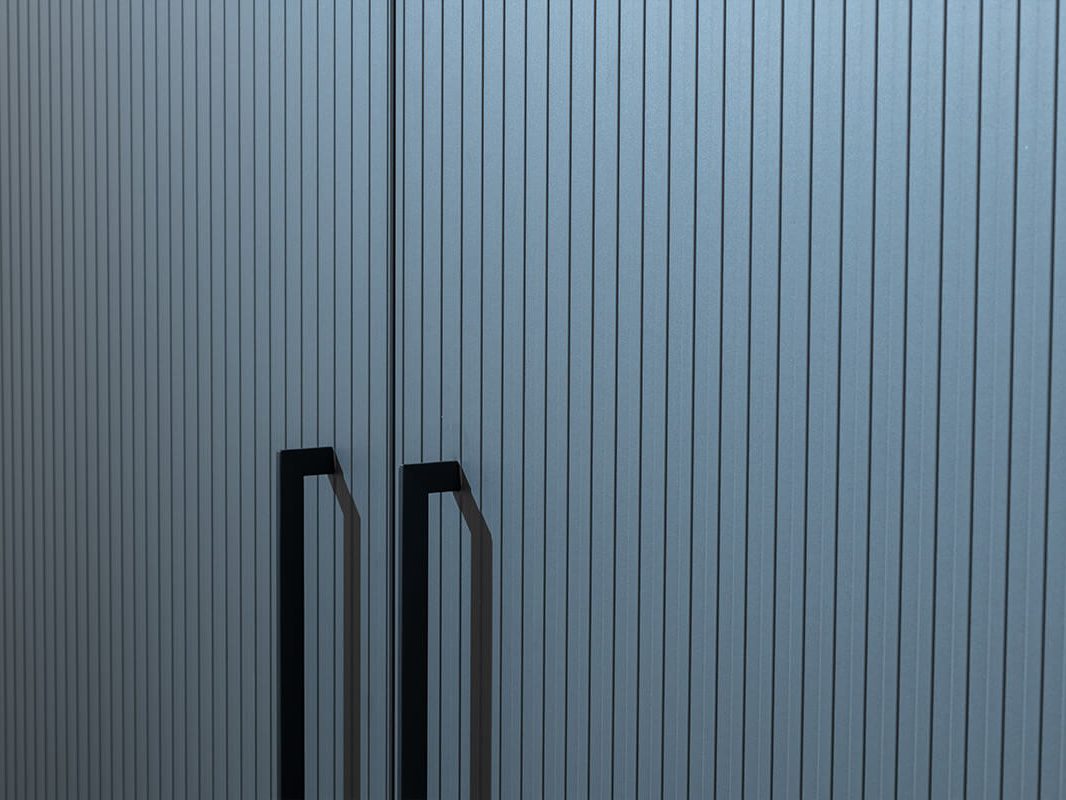

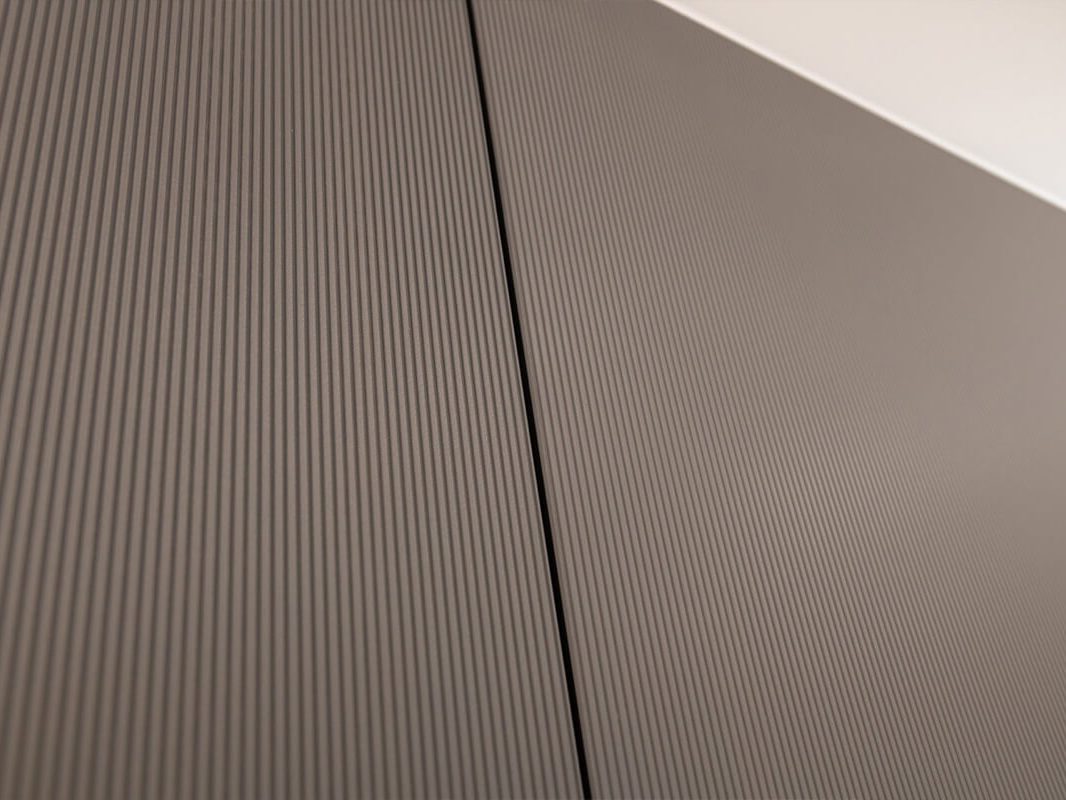

LAMINLAC surface panels are one of the most advanced flat lamination technology products.

They offer a choice from an astoundingly vast catalogue of decorative foils, made with recycled materials, including up to 85% recycled PET, via a process that reduces CO2 emissions into the atmosphere by 60%. The panel itself is also recyclable.

An impressively vast range of colours is available, now updated with a high gloss (95 gloss) or super matt (five gloss) lacquered finish, one perfectly smooth and the other pleasantly velvety.

They both offer excellent resistance to scratches, abrasions and chemical agents. Pigment stability to UV ray exposure and an anti-fade paint layer ensures that colour stays true over time.

Like glass, but safer and tougher than glass

XGLASS panel surfaces are made of a material that looks almost identical to glass but is much lighter and, most importantly, shatterproof, shatterproof, so it is safer than glass. Their 2mm thickness creates a visual effect of depth, which can be enhanced by various processes such as edge finishing.

They guarantee excellent resistance to impact, scratching, chemical agents and exposure to UV light. They are also anti-fingerprint and have antibacterial properties.

XGLASS panels adapt easily to different machining techniques, including bevelled edge finishing. They can be cut and drilled with holes on-site for fitting handles.

A multitude of colours are available, with some always kept in stock.

SERVICES

LOGISTICS AN INTEGRAL COG IN THE PRODUCTION MACHINE

LANTA's mission is to work alongside our customers, turning your brief into tangible solutions: everything from concept to design is part of a joint process so that the resulting solutions are the best match for your requirements.

With our solid and efficient organization, we can reduce lead times and provide you with logistical flexibility, including cross-docking.

QUALITY

CERTIFIED QUALITY CONTINUOUS IMPROVEMENT

Our internal quality system embodies our commitment to continuous improvement across every stage of production: each product is crafted with cutting-edge technologies and meticulous care to offer consistently high standards.

The quality we deliver is more than just a promise, it is a certified achievement: LANTA holds accreditations from international bodies (including FSC®, PEFC® and ISO 9001), attesting to the real-world value of our corporate philosophy.

We follow Total Quality Management principles, applying an integrated approach that fosters innovation and delivers a range of solutions ready to face any challenge. More specifically, our PET-laminated (HG/SM) MDF panels and fronts are made to strict specifications covering everything from the type of facing, backing, edges and even the adhesive used, to ensure top performance and finishes.

LANTA'S EMPLOYEE FOCUS

At ILCAM Group, we place people at the heart of everything we do and back up our commitment with real-world actions. Inclusion, equal opportunities and work-life quality for employees are some of the mainstays of the Group’s policy. Our commitment to looking after our people is actioned through initiatives and solutions that create a safe, healthy and ethically supportive work environment where staff can thrive.